The working principle of plasma cutting machine is based on oxygen or nitrogen as the working gas, use high temperature plasma arc quantity of heat to make the workpiece incision of the metal local melting and evaporation, and with the help of a high speed of the plasma momentum ruled out a molten metal to form a slot of a kind of machining method.

Laser cutting machine is a laser beam of light produced by a laser, through a series of mirror transmission, finally by the focus lens on the workpiece surface, produce local high temperature at focus, make the artifact is added hot melt or instant vaporization slot. And assist in the process of cutting gas would slot in slag blow out, ultimately achieve the purpose of processing.

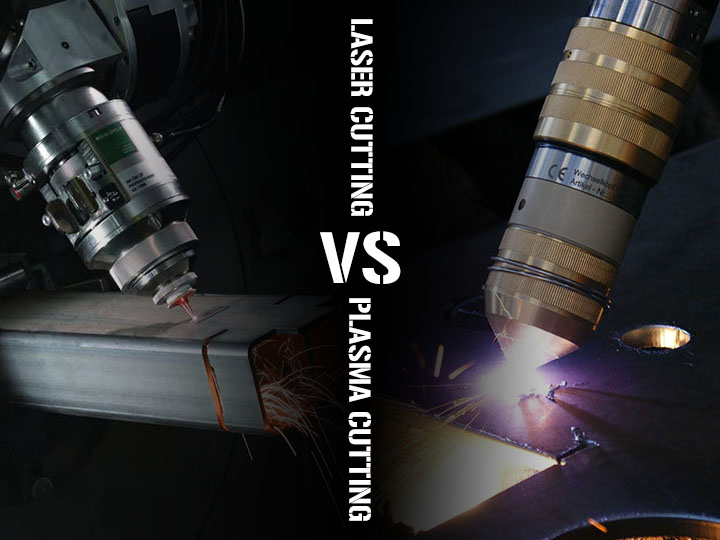

|

| Laser cutting machine VS Plasma cutting machine |

Plasma cutting is suitable for cutting various metal materials, mainly in thick plate cutting. Advantage is cutting speed, narrow slot, small heat affected zone, the deformation is small, operation cost is low; Defect is in the cross section vertical degree is 0.5 ° ~ 1.5 ° Angle, hardening of incision.

Laser cutting, mainly in sheet cutting material range is very wide (metal, nonmetal, ceramics, glass, etc.). Due to the direction of laser with high, high brightness, high strength etc., so the laser cutting speed, high machining accuracy, cutting is very narrow, subsequent processing are generally not required.

To sum up, in terms of cutting materials, laser cutting of material selection range is wider than plasma cutting; In terms of sheet cutting, laser cutting is more significant advantage; And in terms of cost, plasma cutting relative to the laser cutting is a lot cheaper.

Compared with general way of cutting, laser cutting machine has some significant advantages:

1. small laser cutting slot, cutting surface can be directly used for welding, don't need to be polished.

2. laser cutting machine speed: cutting thin plate speed can be up to 10 m/min, much faster than the speed of plasma cutting machine.

3. good cutting quality of the laser cutting machine, small deformation, surface roughness value is low, oblique piece.

4. high precision laser cutting machine, precision can reach 0.05 mm, repetitive positioning accuracy can reach 0.02 mm.

5. laser cutting machine cutting materials widely: besides can cut metal, also can cutting wood, plastic, rubber, PVC, leather, textiles, and organic glass, and other materials, a wide range of application.

The disadvantage of laser cutting machine: laser cutting cost is high, the initial investment and maintenance needs higher cost; At present, laser cutting thin plate high cost performance, but when the cutting plate efficiency is low, unless the quality of the demand is higher, or inappropriate use laser cutting.

The advantage of plasma cutting machine: thick plate in cutting process, can achieve very high cutting speed, far higher than that of laser and flame. Late early than low laser equipment, the maintenance cost is lower than the laser.

Plasma cutting disadvantages:

1. poor perpendicularity of the cut surface: on one side of the cutting surface will produce very big bevel, vertical degree will be poor.

2. to produce more cutting slag on the surface of the cutting process in cutting down cutting slag, as does not affect the quality of the process, after the cutting slag must be through grinding, also increased labor costs.

3. will produce harmful gas and arc: plasma cutting principle determines the cutting process will produce harmful dust and arc, however, at present also appeared to avoid the defect of underwater plasma cutting.

4. cutter consumption will be more late, and now the cutting nozzle mainly depend on import, the cost is higher.

According to the experience of we used before, laser cutting machine and plasma cutter machine is as follows:

1. will not damage parts, laser cutting machine and plasma cutting machine to plank is big or small injury, especially in the process of cutting plasma cutting machine cutting torch nozzle problems arise will cause obvious flaw to the plate.

2. because of the focused laser beam into very small points of light, so narrow kerf width laser cutting machine, plasma cutting machine cutting of the cutting seam than laser cutting machine cutting seam slightly larger.

3. laser cutting machine speed, cutting speed can be up to 10 m/min, much faster than the speed of plasma cutting machine.

4. laser cutting machine cut surface is smooth, without burr, cutting quality is good, is a non-contact cutting, trimming heat effect is very small, almost no thermal deformation of workpiece, completely avoid material formed when punching and shearing edge collapse, generally do not need secondary processing kerf width. But the thickness of the cutting board restricted and high processing cost. And plasma cutter according to the different type and size can be cut power over 6 ~ 40 mm steel plate, processing costs are relatively cheap.

5. high precision laser cutting machine, laser cutting machine positioning accuracy of 0.05 mm, repetitive positioning accuracy of 0.02 mm, but the working environment demand is high, plasma cutting machine, laser cutting machine machining precision is not better than, but low requirements for the work environment and strong maneuverability, adapt to a wider range of cutting, skills water quality requirements for the personnel relatively lower laser cutting.

The advantages of laser cutting machine is cutting accuracy is higher, faster, plate deformation is small, suitable for complex shape parts inventories, but right now my company's equipment, cutting thickness is restricted, generally: 8 mm the following sheet, set piece using the laser cutting machine with relatively high precision blanking, the material cost is higher, to the purity of the plate also to have certain requirements.

The advantage of plasma cutting machine is cutting area wide, can cut all sheet metal; Quick cutting speed, high efficiency; Cutting accuracy is higher than CNC flame cutting, fine plasma cutting has higher precision. Drawback is that cut thick plate, especially more than 20 mm steel plate is difficult, need high power plasma power supply, the high cost.

Original source from https://www.stylecnc.com, if you want to copy, please indicate the primary source:

https://www.stylecnc.com/plasma-cutter/